Content

- History of Vulkan Ltd.

- Business Plan (Quality Policy)

- A brief history of condoms

- Definition of quality

- Testing of condoms

- QFD analysis

- Process production of condoms

- Guarantee of quality

- Product audit

- Project of improvement of the wall thickness of condoms

- Literature

Company VULKAN Ltd. was established in 1890 as one of the first rubber goods factories on the territory of present Czech Republic. In 1892 the company was affiliated to the Berlin-Frankfurter factories producing rubber goods under the name of Veritas. The manufacturing program included technical rubber, all kinds of rubber hoses, -rubber padding and rubber surgical goods.

From 1946 the manufacturing program is gradually changed to its present structure. In 1970's VULKAN has gone through an extensive modernization process. Gradually automatic production lines for all essential types of present production were installed.

In 1992 VULKAN was awarded the prestigious International Leading Company award.

These are represented by gloves for medical service, household and industry, baby pacifiers, inflatable balloons and naturally condoms with trademark PRIMEROS. VULKAN is the only manufacturer of this type of merchandise in the Czech Republic and the most significant in Central Europe.

For the entire duration of its existence VULKAN belongs among recognized producers of rubber goods with a large share of export. During its existence VULKAN has exported its goods to more than 70 countries of the world and retained its status of a much-sought-for supplier due to its large assortment, flexibility and the high quality of the products.

The high standard of quality is demonstrated by the fact that VULKAN received ISO 9002 quality certificate from TÜV Bayern from Germany and its recent award of FDA certificate for the sale of condoms in the USA.

Business Plan (Quality Policy)

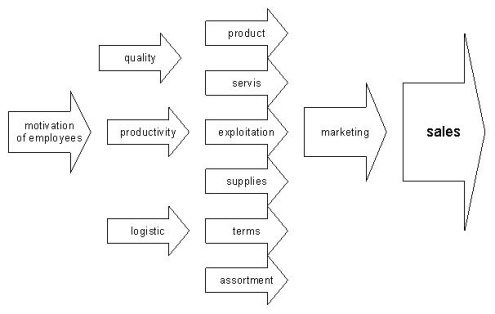

Quality is priority for our company. We don’t express the Quality Policy separately from the Business Plan. The Quality Policy is integrated part of our Business Plan. We express our Business Plan pictorially:

We have these Business Objectives for the year 1999:

- We are going to increase the savings from improving ideas of 25%

- We are going to decrease the fluctuation of employees of 10%

- We are going to increase the absolute value of product audit of 20%

- We are going to reduce the volume of internal scraps of 10%

- We are going to increase the productivity of work per employee of 20%

- We are going to increase the productivity of work per m2 of 10%

- We are going to decrease the volume of supplies of 20%

- We are going to decrease the volume of in course of manufacturing and finished products of 10%

- We are going to decrease the average delivery time of 2 days

- The limit of late supply is 2%

- We are going to extend the assortment of 10%

- We are going to sell of 10% more products for current customers

- We are going to reach 20% of new customers

As a result of these objectives we plan the increase the volume of sales of 25%.

The first evidence of a mechanical device, which covered and decorated male sexual organ and simultaneously protected the woman from conceiving dates from Ancient Egypt from unbelievable date 1.350 B.C. Devices resembling condom were also used by Asian cultures perhaps even before the Egyptians. However we have no specific date at our disposal. On the territory of present Czech Republic the first condom users were probably Celts, who definitely knew this form of anticonception.

Date of birth of the real condom is 1564 A.D., when Italian anatomist Fallopius manufactured a sheath of linen cloth. In 17th century the textile material was replaced by animal intestines, especially sheep intestines. The name of condom dates to this period. Certain scholars believe that condom is named after English physician Conton (some sources mention his name as Condom). This gentleman was the court physician of English King Charles II. (1630-1685). Doctor Conton allegedly supplied the members of royal family and their court specially modified sheep intestines to protect them from "veneral disease and the conception of bastards". Doctor Conton was promoted to noble rank for his meritable service to royal court.

It should be mentioned that its merit for naming condom also contests a French city of that name. The city of Condom however suffers from one problem. The road signs bearing the name of Condom must be replaced regularly. Not even police patrols dissuade the thieving souvenir collectors and thus the tax payers are worse off for their city signs.

The modern style mass production of condoms was started off by the invention of volcanized rubber. At the beginning stands a tree - gumtree, whose resin - latex, resembles milk. The addition of volcanization compounds and other additives results a special latex substance. From this substance a condom is made by the process of dipping on glass forms, drying and volcanization. Typical characteristics of condom are high elasticity and impermeability. The final operations consist of washing the condom, apretation and naturally of thorough and 100% electronical checking control.

The principle of the condom manufacturing process has not changed much since the invention of volcanization. However attitudes to its use and its massive distribution has.

Quality is defined as the file of attributes of product (service) they set the satisfaction of needs and expectations of customers.

This definition is a little complicated (at first sight). When you are thinking about this definition, you remember, that this definition has a simple base: „Quality is the customer satisfaction“

I have the pictorial memory. I draw this picture (for easy storage):

QUALITY = SATISFIED CUSTOMER

I am going to be in the history of quality. I set down my own definition:

QUALITY = SATISFIED CUSTOMER ≠ GUINEA PIG (experimentee)

In that definition I want to point out that we can’t do the experiment with the customer. We can’t give him the product and expect his reaction (satisfied or unsatisfied?). We must GUARANTEE that the customer will be satisfied!

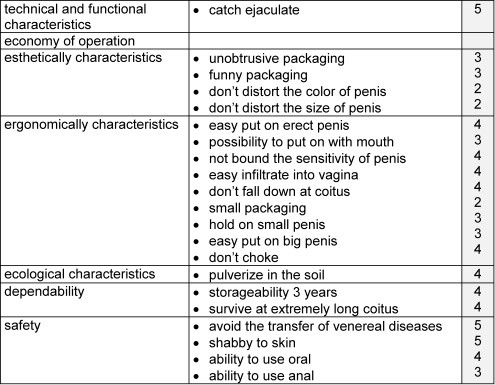

Quality is defined as the file of attributes of product:

- technical and functional characteristics

- economy of operation

- esthetically characteristics

- ergonomically characteristics

- ecological characteristics

- dependability

- safety

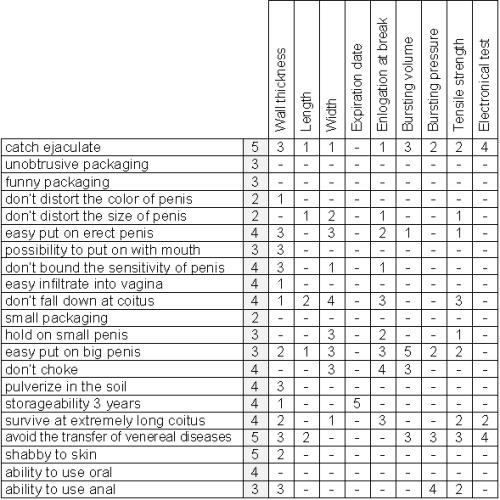

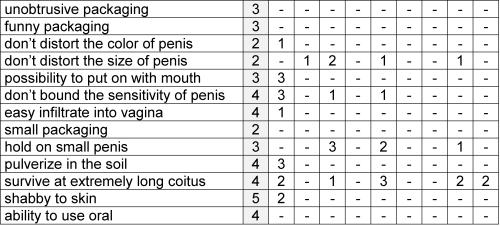

We must identify the customers needs to usual condom:

The weight of customers needs is signed in the last column. We used this scale:

- neglectable requirement: the customer won’t record the filling

- not important: only some customers will record the filling

- medium important: the customers will be unsatisfied, when it won’t be performed

- important: this need affect the function and use of product

- critical: this need affect the health and safety of customer

Condoms, which are sold in European Union, but also in majority of other countries of the world must conform to standard EN 600. According to this standard condoms must comply with the following parameters.

Standard EN 600

PARAMETERS

Wall thickness: max. 0,08 mm

Length: min. 170 mm

Width: 49 - 56 mm

Expiration date: min. 4 years

TENSILE PROPERTIES

Enlogation at break: min. 650 %

Bursting volume: min. 18 l of air

Bursting pressure: min. 1,0 kPa

Tensile strength: min. 18 MPa

Electronically tested: Yes

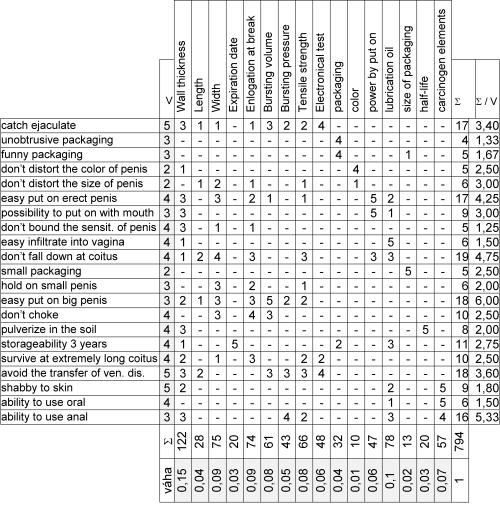

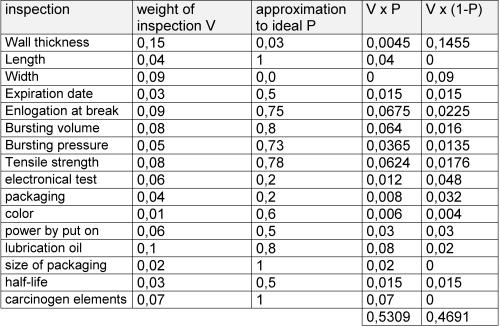

This analyze is comparing the inspection of parameters with customers needs. We suppose that the result of the inspection has been positive. We ask: „How this result assures the fulfillment of customer’s needs?“ We use this scale:

- no relationship

1 some relationship

2 weak

3 middle

4 strong relationship

5 certainty

Empty or week engaged rows reflect that we don’t have the satisfactory inspection for this customer need. We don’t assure the quality enough. In this example we don’t have assured these needs:

In that reason we must add some new inspections in our process:

- inspection of packaging

- color: this assure that the condom doesn’t distort the color of penis

- power by put on the penis: this assure the possibility to put on the condom with mouth

- volume of lubrication oil: this assure easy infiltration into vagina

- size of packaging

- half-life: this assure that the used condom will pulverize in the soil

- content of carcinogen elements: this assure that the condom is shabby to skin

We can see on the right side of the table how strong the customer needs are inspected.

The importance numbers of inspections are in the last row. We can see that the most important inspection is wall thickness.

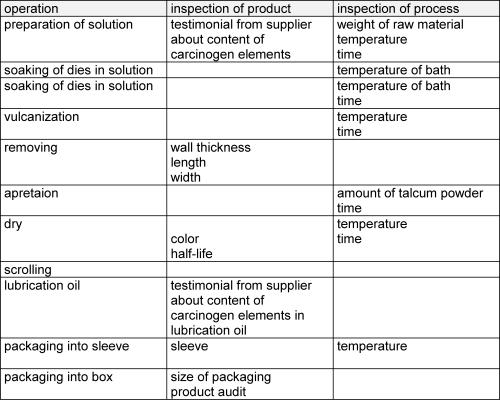

You can see the operations in the first column. The inspections of condom are introduced in the second column. These inspections we can make on the finished condom. The inspections of process are placed in the last column. Inspections of process are important for producer but they aren’t important for customers. The producer can’t use these inspections to guarantee the quality of product.

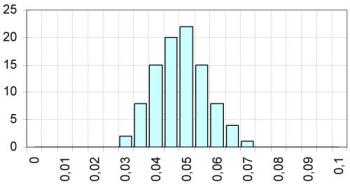

We are going to do a stochastic selection of 100 pieces of condoms. We are going to measure the most important parameter of condom – wall thickness.

We are going to build the histogram from the measuring data.

We are going to count the average value X = 0,0048

and sample standard deviation S = 0,08

We can plot the Normal probability curve for these parameters:

Upper specification limit is in the distance 4S from X. The probability, that some condoms have bigger wall thickness is 32 ppm.

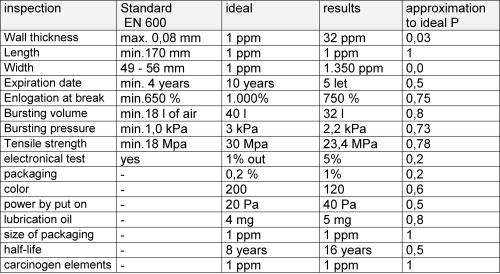

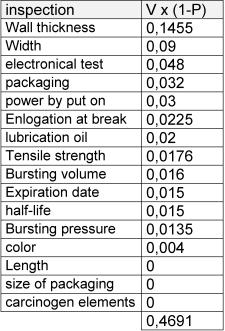

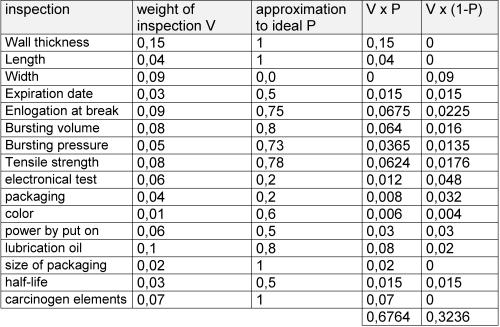

There are recorded the results of inspections in this table. These results are compared to ideal results. Ideal results are the best results reached on the best condoms.

We multiply the value of approximation to ideal by the value of weight of inspection. When we sum this multiplication’s we obtain only one number. This number expresses the attained quality of condom.

The quality of condoms is 53,09 % to ideal condom.

Next table shows where (on which parameter) we lost the quality. The biggest problem seems to be the wall thickness. The inspection of thickness is most important inspection. We expect the guaranty 1 ppm in the ideal case. We guarantee only 32 ppm today.

In the last few rows of this table we can see these parameters, these aren’t suitable to improvement. Every improvement spends some money, needs some workforce and time. We must invest deliberately. The money invested in the parameters there are written in the top rows will return even soon then the money invested in the parameters there are written in the bottom rows.

Project of improvement of the wall thickness of condom

1. Definition of problem

The problem is the sample standard deviation. (Most of firms have problem with sample standard deviation. They don’t know that they have this problem.) = 0,048 When we want the guarantee 1 ppm then the upper specification limit must be in the distance 5S from X. The sample standard deviation should be S = 0,0032. We need the reduction of sample standard deviation from S = 0,0080 to S = 0,0064

2. Institution of action-team

We instituted the action-team. The members of the team were:

- John Novak - technologist

- Peter Bezruc - foreman

- Joseph Svoboda - engineer

- George Chaloupka - quality consultant

3. Description and recognition of problem

All the members of the team made an acquaintance with the problem. They described the parameters of process and results of inspections.

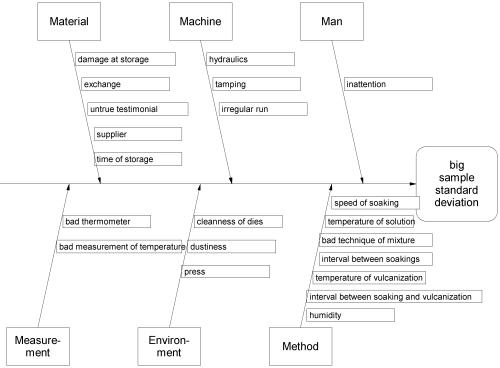

4. Cause analysis

The team used the Ishikawa diagram to determine the causes of the problem:

The team determined the most probable factors there are influencing the sample standard deviation. We determined these factors:

- speed of the soaking

- temperature of the solution

- interval between two soakings

- interval between soaking and vulcanization

- humidity

- press

- supplier

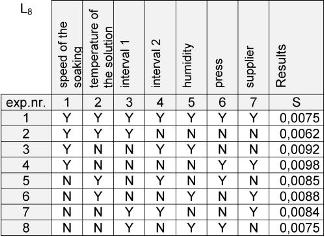

5. Action plan, realization of experiments

6. Analyze of experimental dates

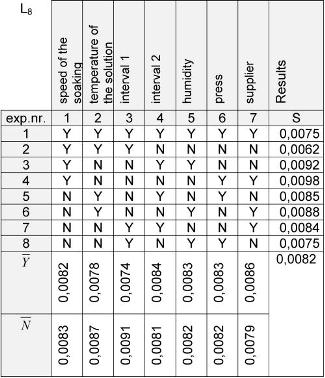

The members of the team resolved to look for the solution of this problem through design of experiments. They made up one's mind to use the process of DOE from Genichi Taguchi. They planed 8 experiments to find the best combination of parameters of process. Each parameter was planed in two levels: Y - means to do the change, A – means not to do the change.

You can see the results of experiments in the last column. We inspected 50-time wall thickness in specified conditions and we figured up the sample standard deviation. Analysis of experiments:

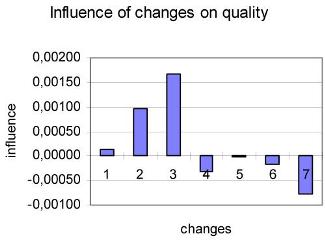

We figured up Y - N and plotted next graph:

From this graph we can deduce the next conclusions: It will be better

- change the speed of the soaking

- change the temperature of the solution

- change the interval between two soakings

- don’t change the interval between soaking and vulcanization

- don’t change the humidity

- don’t change the press

- don’t change the supplier

We can see the most important requirements from this graph: change the interval between two soakings and change the temperature of the solution. These columns are the biggest and these factors are the strongest. The least important requirements are change the speed of the soaking, don’t change the humidity and don’t change the press.

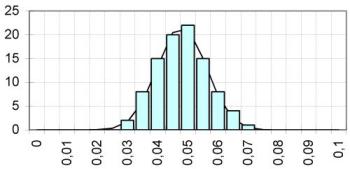

7. Proving experiment

Team performed one proving experiment. We used the ideal conditions (ideal levels of factors). We obtained the result S = 0.0062. This result confirmed the results of our analysis.

The upper specification limit is in the distance 5S from X. The probability, that some condoms have bigger wall thickness is 1 ppm now. This result is changing our value of product audit:

The last value of product audit was 53.09 % to ideal. The presents value (after improvement is 67.64 % to ideal.

8. The action to stabilize the change

All the changes were documented. The process of improvement was recorded in the form: "Corrective and preventive action" This form is archived at Quality Manager.

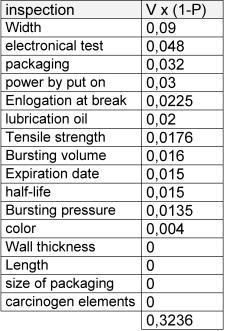

9. Other improvements

We are going to increase the absolute value of product audit of 20% in our business objectives. We reached the increase of 14.5% after improvement. We must to continue. Next table shows other themes to improvement:

- http://www.vulkan.cz

- ČSN EN ISO 9001,Quality management and quality system elements – Model for quality assurance, development, production, installation and servicing. ČNI, 1995

- ČSN EN ISO 9004-1, Quality management and quality system elements – Part 1: Guideline, ČNI, 1995

- Quality management system requirements QS-9000. Magazine ČSJ, 1997

- VDA 6.1, Quality management in automotive industry. Audit of quality management systém. Magazine ČSJ, 1996

- VDA 5 Quality management in automotive industry. Product audit. Magazine ČSJ, 1994

- V. Dolanský, V. Měkota, V. Němec: Project management. Grada, 1996

- J. Václavek: Quality Function Deployment. Magazine ČSJ, 1993

- ČSN O1 O250: Statistical methods in industry. ÚNM, 1972

- R. Roy: A Primer on the Taguchi Method. Competitive Manufecturing Servise

- K. Ishikawa: What is companywide quality management, Japanese way, ČSJ, 1991

- R. Vlček: Value management. Management Press, 1992

- A lot of other authors. I don’t remember what I learned from them. I apologise and thank.